Features

The function of the lightning arrester is to protect various electrical equipment in the power system from damage caused by lightning overvoltage, operating overvoltage, and power frequency transient overvoltage. The types of surge arresters mainly include protective gaps, valve-type surge arresters and zinc oxide surge arresters. The protection gap is mainly used to limit the atmospheric overvoltage, and is generally used for the protection of the incoming line section of the power distribution system, lines and substations. Valve-type surge arrester and zinc oxide surge arrester are used for the protection of substations and power plants. In systems of 500KV and below, they are mainly used to limit atmospheric overvoltage, and also used to limit internal overvoltage or internal overvoltage in ultra-high voltage systems. Backup protection against overvoltage.

LED anti-induction surge technology

LED anti-induction surge technology

LED anti-induction surge technology

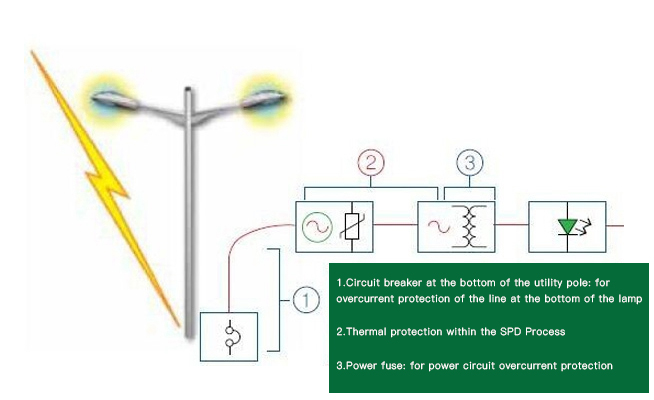

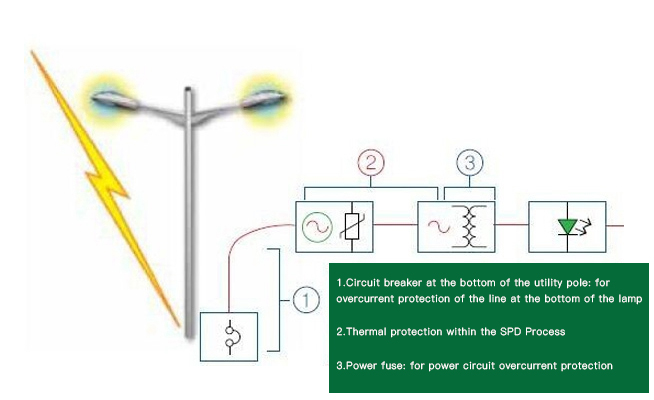

LED anti-induction surge technologyThe way to protect outdoor LED lighting from induced surge damage is to block high voltage/current transients from entering the lighting fixture. Therefore, a surge protector (SPD) can be used in outdoor LED lighting applications to suppress surge energy and minimize surge impact on lighting equipment.

For SPDs, a variety of overvoltage protection components are available, including metal oxide varistors (MOVs), gas discharge tubes (GDTs), and transient voltage suppression (TVS) diodes. These components are placed between AC power lines, which typically have high impedance, and become low impedance when high voltage is detected. In the low-impedance state, these components can transfer surge energy back to the AC power line, and back into the high-impedance state after a surge event. Among the existing technologies, MOV is the most suitable technology for surge protection devices in outdoor LED lighting applications because of its high surge energy handling capability and fast response to transient voltages. GSPD series LED street light lightning arrester Shenzhen Greenway Electronics Co., Ltd.

Incorporating a surge suppression circuit into an outdoor light fixture can eliminate damage caused by surge energy, thereby increasing the reliability of the lighting fixture, minimizing maintenance and increasing service life. A surge protection component that suppresses excessive surges to lower voltage levels is the best way to protect LED lighting installations.

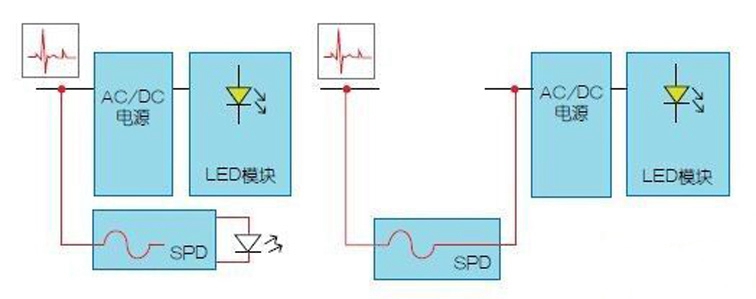

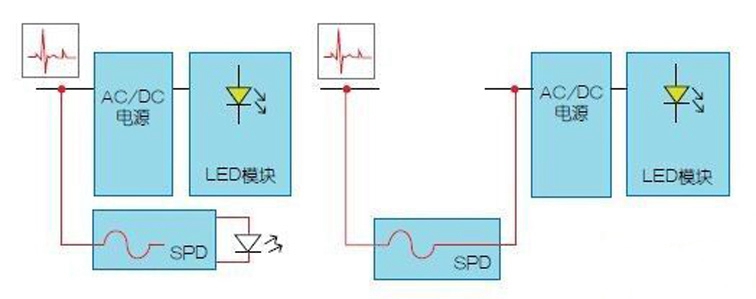

Figure 1: LED street light protection scheme.

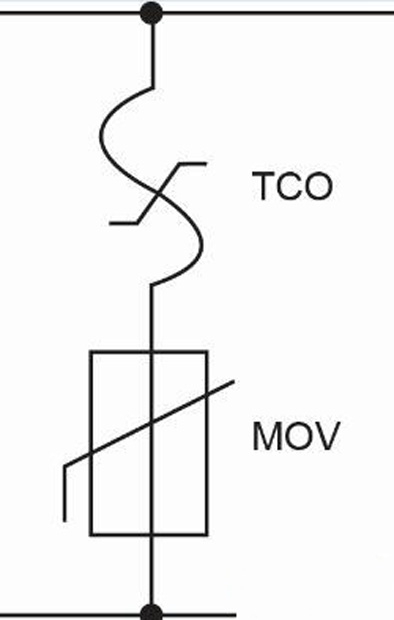

Thermally Shielded MOVs Keep SPDs Safe

Metal oxide varistor (MOV) technology is a very effective technique for suppressing transients in power supplies. This technique is also effective in many other applications, such as surge protector (SPD) modules typically placed in front of LED drivers.

After a large surge or multiple small surges, the performance of the MOV will gradually degrade. This degradation leads to increased metal oxide varistor leakage current, which in turn increases the temperature of the MOV, even under normal conditions of 120VAC/240VAC operating voltage. A thermal circuit breaker adjacent to the MOV can be used to detect an increase in the temperature of the metal oxide varistor when it continues to degrade to an end-of-life state. At this time, the thermal circuit breaker will open the circuit and remove the degraded varistor removed from the circuit to prevent catastrophic failure.

Figure 2: Thermal circuit breakers prevent a degraded MOV from failing.

Figure 2: Thermal circuit breakers prevent a degraded MOV from failing.MOVs are designed to clamp fast overvoltage transients in microseconds. However, in addition to short-term transients, MOVs in SPD modules are also subject to temporary overvoltage conditions caused by missing neutral or incorrect wiring during installation. These conditions can create a thermal runaway condition for the MOV; in turn, this can lead to overheating, smoke, and even fire. The safety standards for SPDs, UL 1449 and IEC 61643-11, define specific abnormal conditions under which devices must be tested to ensure SPD safety. In a robust design, a thermal circuit breaker is incorporated inside the surge protector to protect the MOV from thermal runaway.

Figure 2: Thermal circuit breakers prevent a degraded MOV from failing.

Figure 2: Thermal circuit breakers prevent a degraded MOV from failing.

Figure 2: Thermal circuit breakers prevent a degraded MOV from failing.

Figure 2: Thermal circuit breakers prevent a degraded MOV from failing.● Parallel connection: The SPD module is connected in parallel with the load. While an end-of-life SPD module is disconnected from the power source, the AC/DC power supply unit remains powered on. The lighting is still working, but it loses its protection against the next surge that the power unit and LED modules face. In a parallel SPD module, a replacement indication can be provided by using a small LED that indicates the status of the SPD module to the maintenance technician. You can choose to use a green LED to indicate that the SPD module is online, or a red LED to indicate that the SPD module is offline. Alternatively, the need to replace an SPD module can be displayed remotely in a lighting management center where the SPD module end-of-life indicator line is connected to a networked smart lighting system, rather than installing LED indications on each fixture.

● Serial connection: The SPD module is connected in series with the load. When the SPD module at the end of its life is disconnected from the power supply, the light will be turned off. A power outage to the lamp can be used as an indication to call for maintenance. A disconnected SPD module not only extinguishes the lighting as an indication of replacement, but also isolates the AC/DC power supply from subsequent surges. The general preference for this configuration has grown rapidly because the lighting fixture is still protected while the SPD modules are awaiting replacement. Replacing only the SPD modules in series is much less expensive than replacing the entire luminaire with SPD modules in parallel.

Summarize

In order for LED lighting equipment to reach its expected lifespan, a surge protection module should be incorporated into outdoor LED lighting to prevent early failure due to lightning surge events and other power line surges. The surge protection module installed at the front of the LED power supply unit provides effective protection for the lighting system. However, it may be subject to temporary overvoltage threats and fatigue from multiple surge events. Thermal circuit breakers placed in the surge protection module improve the overall safety of the module.